Characteristics of High Density Polymer:

- High quality: The roller shell is manufactured from HDP (High Density Polymer) with impact resistant, acid resistant, anti-corrosion, anti-alkali in chemical character. The roller is assembled well with double cap bearings, in compliance with ISO standards.

- Heavy rigid and high impact performance: Different from the steel roller, Cannings synthetic roller has good impact and instauration. Strengthened frame offers the synthetic roller the same rigidity as a steel roller.

- Excellent waterproof and anti-dust: Cannings synthetic roller provides triple bearing protection. Seal rings prevent water and dust from entering into the inside of the roller. Special catchment groove utilising centrifugal force keeps the inside of the roller dry in all weather conditions. The patented triple labyrinth seals offer a 45% higher efficiency of preventing water and dust than traditional labyrinths.

- Higher efficiency: Ejection body, homogeneous mass, good roundness minimum rolling factor, durable for high speed operation, power saving, noise free.

- Light weight: Cannings synthetic roller is 55% lighter than traditional steel roller, suitable for small drive, head pulley and tail pulley, it can save ¼ cost for power and equipment cost.

- Low maintenance cost: Long service life (guarantee for two years under normal operation), no lubrication oil needed, easy replacement, reduce maintenance labour and time to the minimum.

- Specification: Tube - 102mm diameter x 8mm wall thickness

127mm diameter x 8mm wall thickness

Shaft – Bright drawn mild steel

Stock sizes for polymer idlers are 500mm 600 750 800 + 900mm (for polymer idler set)

Related documents

Related parts

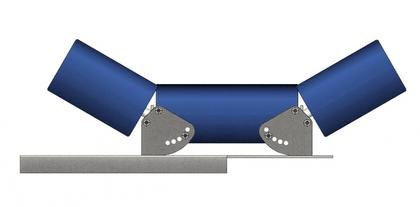

Variable angle sets and returns

An extensive range in stock with adjustable wing rollers ranging from 20° to 60°, enabling the belt to run at conventional or deep troughing angles, with all the advantages our polymer rollers have to offer.

Light weight for easy installation, non-stick with triple labyrinth seals for longer life and 8mm shell thickness.

Fixed angle idler sets and returns

Fixed angle idler sets have end supported wings for extra strength. All rollers are interchangeable and being polymer, are light weight for easy installation, non stick with triple labyrinth seals for longer life and 8mm shell thickness.

The range offers a choice of frames:

- Folded construction, where cost is a determining factor

- Tubular construction, where self-cleaning is a priority

Anderson Maver type returns

Canning high density polymer return rollers are light weight for easy installation. Non-stick with triple labyrinth seals for longer life and 8mm shell thickness, and available with short or long spindle lengths. We stock keyhole brackets to suit.

Field conveyor suspended sets

Canning polymer suspended sets offer many new features:

• New ‘safety handles’

(In HDP polymer or galvanised steel).

Reduced manual handling and trapped finger hazards.

• Easy to install and fit – one man job!

• Lightweight flow friction

• Noise reduction – environmentally friendly!

Up to 8 decibels quieter than steel!

Excellent for locations where noise levels are an issue.

• Non-stick, high density polymer

Polymer rollers don’t stick.

• Wear rate – excellent compared with steel! Very durable.

• Power efficiency – reduces power requirements (amps).

• Triple labyrinth seals for longer life.

• 102mm and 127mm diameter rollers.

• 25mm diameter precision bearing and scales.

• 8 Gauge (4.06mm) shell on steel rollers.

• 8mm shell thickness on polymer rollers.

Return rollers

Canning high density polymer field conveyor rollers are light weight for easy installation. Non-stick with triple labyrinth seals for longer life and 8mm shell thickness